Huzhou jiutong logistics machinery co. LTD

Mobile phone: ms shi 18057236668 / ms CAI 18906723681

Email address: sabrina@jiut.net

Website: www.jiut.net

Address: huzhou and fu town tao jia dun village

Website : en.jiut.net

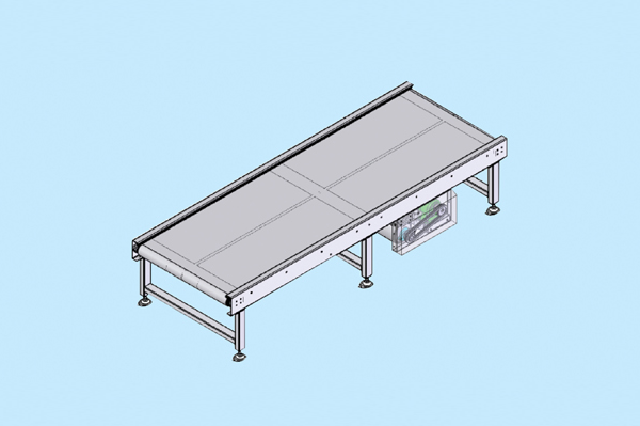

Roller operation situation for the running of the whole conveyor, power consumption, the service life of the transportation cost and so on all have great influence, so the maintenance and replacement of the belt conveyor roller is an important part of the belt conveyor running costs, lost in the next small make up is to introduce to you why not flexible belt conveyor idlers and solution.

One, belt conveyor roller operation is not flexible reasons

The flexibility of idler operation is mainly affected by the following aspects:

(1) quality of idlers: the main change here is that the stiffness of the bearing seat is not enough, and it is difficult to ensure the assembly accuracy of idlers, thus restricting the flexibility of idlers' operation

(2) sealing lubrication and operation and maintenance: due to the poor working environment of belt conveyor, generally it is a dusty environment, and the sealing of bearing seat has a great impact on the flexibility of idler operation. If the sealing is not good, pollutants can easily enter into the bearing and thus cause the idler to rotate inflexibly.

Second, for the idler operation is not flexible measures taken

(1) in terms of belt conveyor idler sealing and lubrication, the equipment should be equipped with qualified lubrication materials. If lithium grease is used, the lubrication condition can be well improved, which plays a good role in extending the service life of idlers.

(2) bearing mainly adopt centripetal ball bearings to support, plastic seal ring labyrinth seal structure, so that we can ensure the belt conveyor idlers work is force is reasonable and has good dustproof effect, and to reduce the resistance, and more convenient installation and easy to maintain, can effectively reduce the operating cost of the conveyor.

(3) in the production process of idler, the requirements of precision should be guaranteed. For example, the internal control precision of stamping bearing seat should reach level 3, the dimensional tolerance, coaxiality and ellipticity of both ends of the tube body should meet the standards, and strict quality inspection should be conducted for the products. Only after the products are qualified can they leave the factory.