Huzhou jiutong logistics machinery co. LTD

Mobile phone: ms shi 18057236668 / ms CAI 18906723681

Email address: sabrina@jiut.net

Website: www.jiut.net

Address: huzhou and fu town tao jia dun village

Website : en.jiut.net

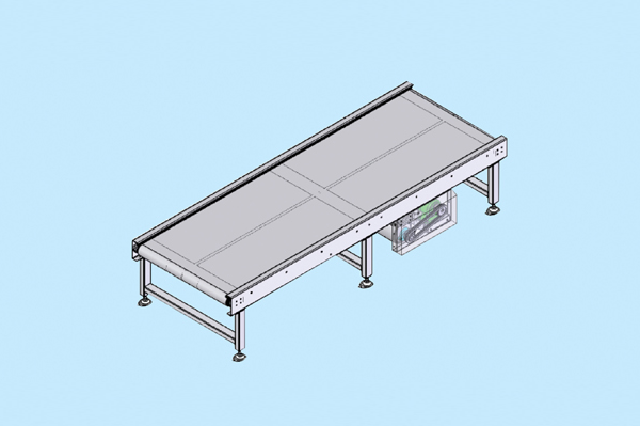

Belt machine we should not be unfamiliar, the now has become a popular choice of high quality products in major occupations, but it has some problems in the process of processing, about this information, let's have a detailed understanding:

1. Shortcomings of welding seam: the defects of welding seam are serious. Manual mechanical polishing is adopted to compensate for them.

2. Inconsistent appearance: only pickling and passivation of welding seam will result in uneven appearance and affect beauty. 3. Equipment elements: in the rolling and bending process of profiles and plates, scratches and creases formed are also the main causes of corrosion after treatment.

4, limited pickling ability: pickling passivation paste is not universal, plasma cutting, flame cutting and black oxide skin, difficult to remove.

5, uneven polishing and passivation: belt conveyor manual polishing after pickling passivation treatment, large area of the workpiece, it is difficult to reach uniform treatment effect, can not get the ideal uniform appearance. And labor costs, accessories costs are higher.

6, scratches difficult to get rid of: overall pickling passivation, can not be processed in the process of all kinds of scratches removed, and can not remove because of scratches, welding spatter and adhere to the surface of stainless steel carbon steel, spatter and other impurities, resulting in the presence of corrosive medium conditions of biochemical corrosion or electrochemical corrosion and rust.

7. Severe scratches caused by human factors: in the process of hoisting, transportation and structural processing, scratches caused by knock, drag, hammer and other human factors are severe, which increases the difficulty of appearance treatment and is also the main cause of corrosion after treatment.

8, other elements: stainless steel raw materials in the procurement, storage process, because the lifting, transportation process bump and scratch is also serious, is one of the causes of corrosion.

Belt conveyor manufacturers. Glass, food conveyer, refrigerating machinery, dishwasher, stainless steel, chain plate, various special shape, sprocket, and undertake design and installation, we provide you with the best products, the lowest price, the most thoughtful service. Our factory sells more than 1000 customers all over the country and enjoys a high reputation in the glass industry in China. Our factory has outstanding overall quality and strong technical force, advanced production technology, complete equipment. With respect for talents and development of science and technology, the glass machinery is developing rapidly to automation today. At the moment when the glass bottle and jar profession is competing with each other overnight, in order to meet the need of glass products career development, the spirit of importing machinery localization and digestion and absorption is put forward by the relevant departments of the state.

Belt conveyor popular throughout the country, belt conveyor by users welcome. Disassembly should be correct in disassembly of stainless steel, some people not only pry the way of stainless steel is not appropriate, and the use of things is not stable, like a blade may be sharp edges and corners of the thing will scratch stainless steel may draw an imprint, such, stainless steel in high-speed operation, it will make crack gradually expand and crack. Replacement should be reasonable some people in the choice of stainless steel, do not pay attention to the type or specifications, more than a group of stainless steel interlaced, perhaps the old and new different. In this way the tightness of stainless steel must be different, and then be broken. So, the replacement of stainless steel, it is necessary to group replacement, never arbitrarily add may reduce a stainless steel. If a stainless steel tube is used to transfer power, it will obviously break off quickly, which will reduce the efficiency of the engine. To prevent oil and water pollution, oil, water, and cool days insolate on stainless steel will not only affect the transmission performance, increasing, slide down the transmission efficiency, and after a long time to make its metamorphosis, shorten the using life, it should be used in the prevent stainless steel with oil or stained with mud, often should wipe out the tape in the groove of dirt, belt conveyor and should try to prevent exposure to cool day, in order to prevent the tape aging disintegration.