Huzhou jiutong logistics machinery co. LTD

Mobile phone: ms shi 18057236668 / ms CAI 18906723681

Email address: sabrina@jiut.net

Website: www.jiut.net

Address: huzhou and fu town tao jia dun village

Website : en.jiut.net

Pallet is a powerful helper for loading goods and logistics transportation. It can effectively cooperate with the forklift truck and greatly improve the work efficiency of the enterprise. Pallets also protect goods in storage during transportation and handling.

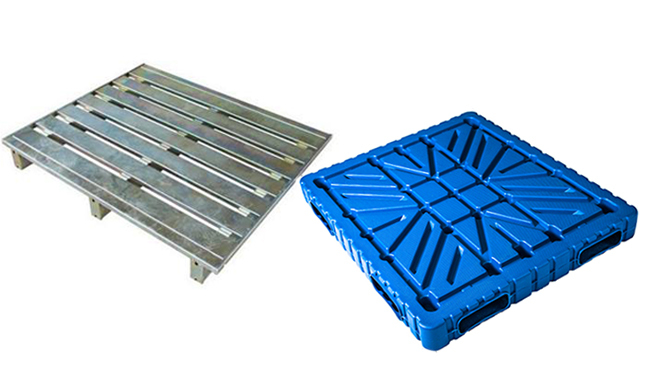

Plastic tray and steel tray function the same, but the production cost is different. Which is better, plastic tray or steel tray? What are the advantages and disadvantages? Want two choose one, small make up give you advice.

First, bearing difference

That difference is now almost non-existent. Double-sided blow molding tray load bearing and steel tray almost the same, plastic tray load bearing capacity is superior, at the same time because of the ability of light weight, more convenient to use management, and received more and more people's favorite.

Ii. Material differences

Steel tray is the raw material is metal material, use for a long time will have wear, corrosion, rust and other chemical substances, not suitable for loading food, medicine and chemical industry, etc., loading products have restrictions.

Plastic tray is usually non-toxic, green plastic products, in wear and tear will not produce harmful substances. Plastic tray corrosion resistance, and because of its own design can be customized, almost all kinds of industries can be perfectly adapted.

Third, cost differences

This is the biggest difference between the two kinds of pallets. The cost of steel pallets is much higher than that of plastic pallets, but the service performance is not better than that of plastic pallets. Steel pallets are expensive and can only be used in certain industries. Plastic tray to adapt to the industry's ability to be stronger, recyclable use is to reduce costs.

Automatic logistics manufacturers welcome to inquire!