Huzhou jiutong logistics machinery co. LTD

Mobile phone: ms shi 18057236668 / ms CAI 18906723681

Email address: sabrina@jiut.net

Website: www.jiut.net

Address: huzhou and fu town tao jia dun village

Website : en.jiut.net

What are the requirements for the structure and manufacturing method of roller equipment? The following roller manufacturer tells you:

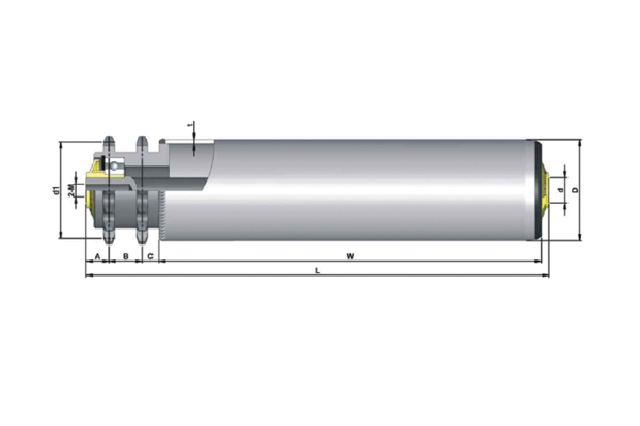

The roller is the main part of the plastic bottle blowing machine. The roller body is generally made of seamless steel tube. The end plate, shaft and the roller body are welded together and formed. The working face width of the roller is generally larger than the width of the die lip of the molding die, which is 50-100mm.

The order of mechanical processing and manufacturing of stick barrel is as follows.

(1) with thick wall seamless steel pipe (wall thickness accounts for 12mm) blanking.

(2) according to the thick wall tube inner diameter as the reference alignment, car tube end face and with the end plate to match the circle (according to 118/k7 precision), car end plate to match the part of the circle and the inner hole, axle to match the part of the circle diameter.

(3) use a square ruler to find the right. Weld shaft and end plate, then end plate and roll. Before welding, use the square ruler to find out the fit verticality of the two welding parts. When welding, first do diagonal spot welding, and then weld the whole circumference.

(4) welding roller body blank annealing treatment, eliminate welding stress.

(5) thick car parts, set aside 2~3mm processing allowance.

6 conditioning and tempering treatment;

7 his fine parts, leaving roller grinding. Other parts are processed according to the size of the drawing.

Grinding roll surface to figure size.

9 (9) roller plated hard chrome layer, chrome layer thickness should be greater than 0.20mm.

Grinding roller flour